“Come On, Baby! Do The Magic Hand Thing!”

-Greef Karga, from “The Mandalorian“

I remember, at the age of fourteen, running around my grandmother’s backyard and pretending to have a lightsaber and desperately attempting to feel the Force flowing through me. It was around 1998 or 1999, and I had just seen the special edition of “Return of the Jedi”. Other fourteen year-olds I knew were busy with sports, or having girlfriends, or smoking cigarettes, drinking, or doing drugs. In other words, doing nearly anything but pantomiming a nearly fifteen-year-old sci-fi-fantasy film in a relative’s backyard, but there I was. By that point I had been neck deep in the lore of Star Wars for years. I had all the books- from the Jedi Academy series and Tales of the Bounty Hunters, to the books detailing the technical specifications of the weapons, technology, vehicles, and alien races. I played Dark Forces and Dark Forces II: Jedi Knight, Jedi Knight II, Shadows of the Empire, and half a dozen others. I knew the legacies of Dash Rendar, Kyle Katarn, and how to make a Ruby Bliel. I had the soundtrack to all three films, each on double cassette. I hadn’t tasted the kool-aid: I had dove headfirst into a vat of the stuff.

What this type of fixation does in younger people, as any nerd-dom member will tell you, is allows one to cultivate a rich inner life and vivid imagination for things. It also teaches one to see the magic where one would not normally expect to see it. This is why many nerds grow up to be incredibly interesting and capable adults.

On top of this, everyone experiences times when they find it difficult to see the magic in life. Falling down rabbit holes teaches you how to nurture yourself when everything might not be so inspiring. The thing that has always saved me is remembering what it is to feel the mystery of it all. The past year has been an exercise in this. Most of my work has been cancelled due to Covid and as of yet has not come back. No knife shows, no gigs, minimal commissions. One of the bright spots of this whole debacle has been season two of the Mandalorian in the fall and winter of 2020. When you’ve been stuck at home doing menial pandemic work just trying to pay the bills, there are few things like a person of a mysterious creed and badass armor having interstellar adventures with Carl Weathers and Bill Burr and a Force-sensitive baby Yoda. Every week I tuned in like I was fourteen. It’s deeply reassuring to know that during such troubled times there are things to make you remember why you pursue that which you value and help you to feel the magic in everything.

For me this is the beauty of having a small custom knife shop. You can do anything you like. There are limitations, the greatest being time, but almost anything that you can think of you can usually do (provided you have the patience.) In this respect, it’s important to keep the mind limber and receptive to creativity for when the muse strikes us. If I am not inspired, I know how to find those things because I’ve been doing it since I was little. Sometimes it’s podcasts, or a song, or a line from a book, or perhaps even a conversation or something I’ve eaten. Because of the pandemic and not going out into the world in my accustomed fashion, this has been quite challenging most days. If I can stir myself, then i can certainly stir someone with a knife I’ve built. If I’ve done that, then my job is complete.

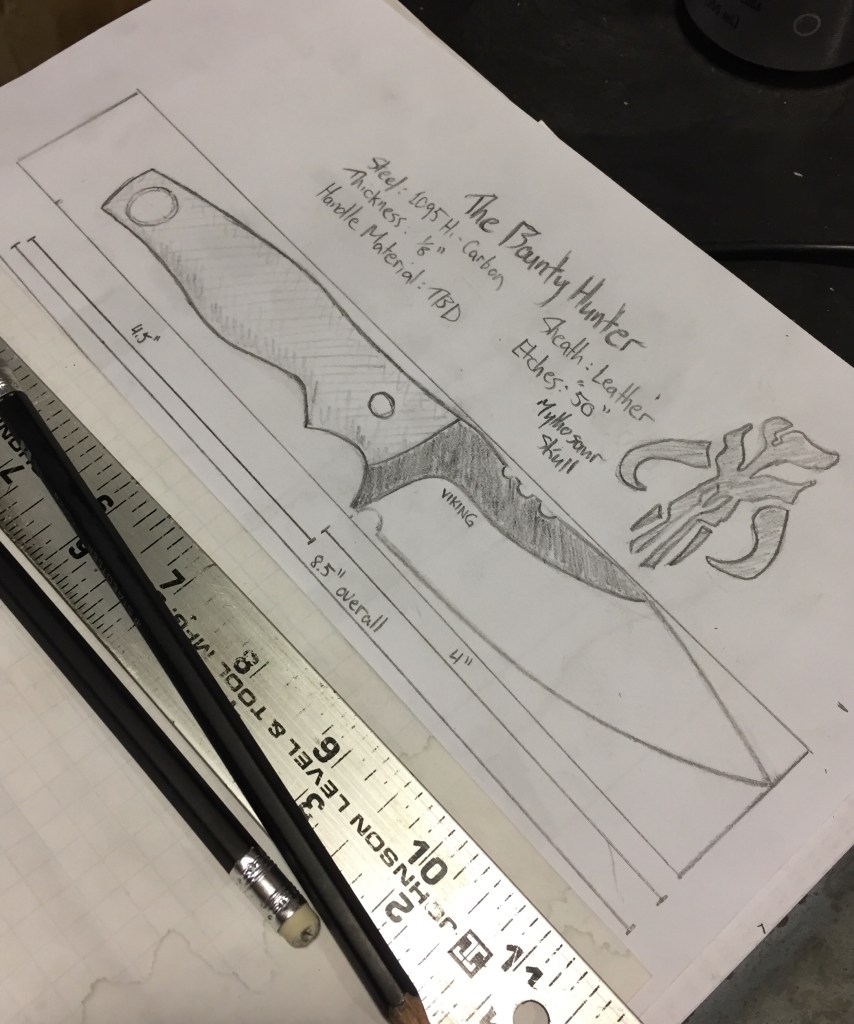

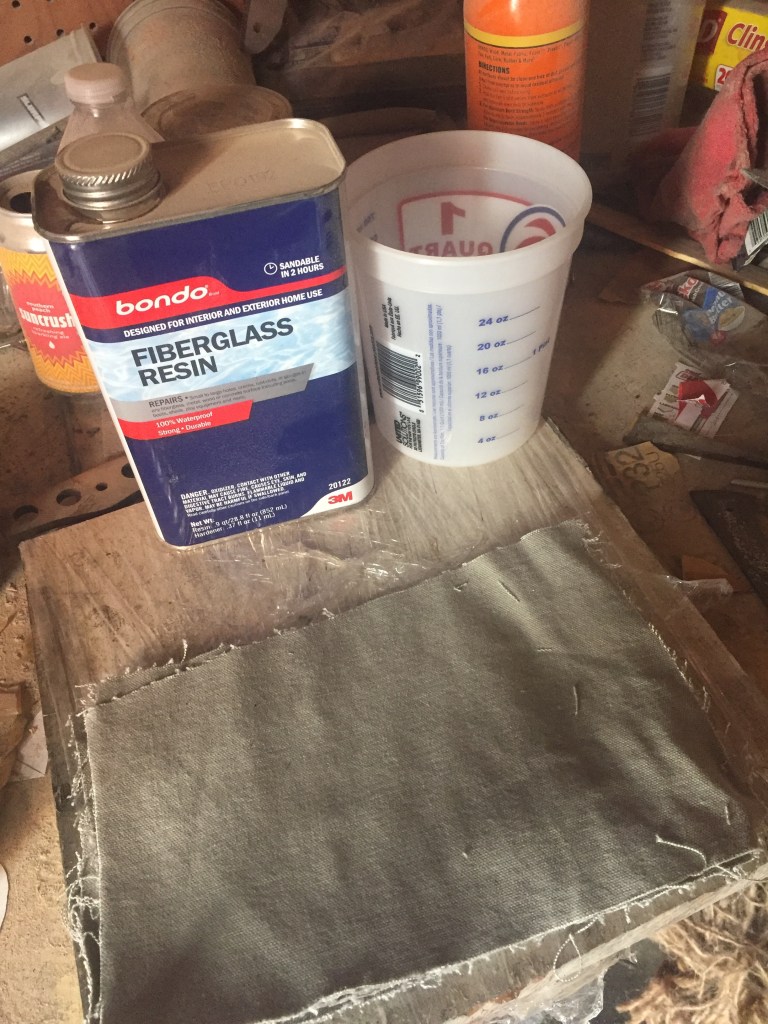

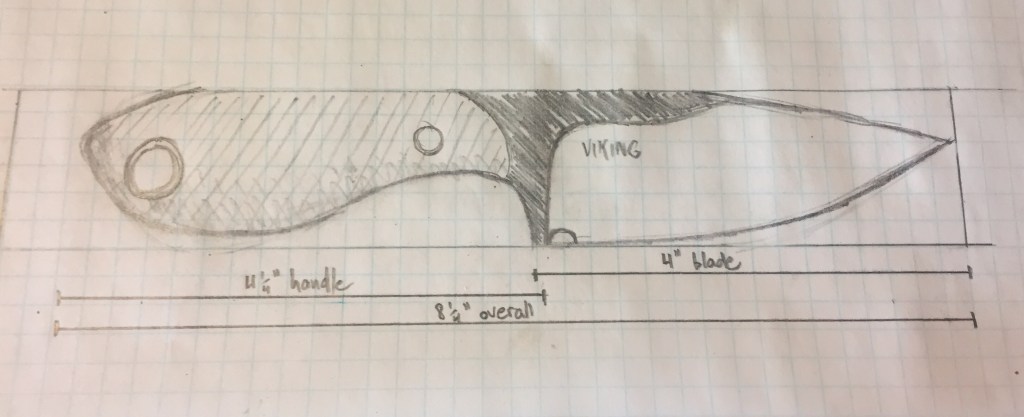

But sometimes we get commissions where WE are the ones who get stirred. We prefer to do everything in house and make sure the work comes from our own hand. While we don’t outsource tasks very often, occasionally we’ll get a commission that is interesting to us and requires that we do so. I received and email from a very good customer asking if I could get a Mythasaur skull on a custom blade and sheath. I thought of how the Mandalorian was such an oasis during a tough time; my own personal magic-hand-thing. I came up with a design that I hoped could fit a Mandalorian bounty hunter and found a laser engraving company in town. Chase your muse, do the work, and walk your path, don’t give up. It’s a journey but this is the way.