A few days after Christmas in 2018 I got a call from a buddy of mine. He was a producer for a company that put together wedding bands and he had to get a group together for a New Years Eve party. He really needed a trombone player for the horn section and gave me a call because I am a trombone player and he knew I probably didn’t have a gig. The problem was I had just had a bit of orthopedic surgery and wasn’t sure I was up for it. He then told me what it paid and said all I needed to be able to do was get a horn up to my face. I told him I was down like a clown, Charlie Brown.

Just doing that gig put me on a list of musicians and I started getting calls. Over the years I’ve been up and down the mid-Atlantic playing in horn sections of wedding bands at country clubs, theatres, mansions, and sometimes out in fields. These are good gigs because the job is to help people have a good time on what is probably one of the happiest days of their lives. With open bars, this is usually not hard at all. Sometimes the receptions are super simple. Others are more involved with lots of moving parts, including musical cues, choreography, and spectacle. One couple at a vineyard wedding were huge anime fans and our producer orchestrated an arrangement of the theme from ‘Cowboy Bebop.’ I played at a Persian wedding were the mother of the groom performed something they called ‘The Knife Dance’, which (as one may assume) involves dancing with the knife that cuts the cake, and passing it through all the women in the family while everyone tosses money at them. The knife finally ends up in the hands of the bride, who cuts the cake.

The band is just a small piece of all this but from the stage you can see all the little pieces of things coming together- the cooks working out of sight, the catering people running food, the sound guy handing out microphones, and event people making sure important people are where they’re supposed to be. All this adds up to something that the guests remember for for years. As one of those tiny little pieces, I’ve found some of my happiest professional moments at these jobs.

Sometime in January of this year a gentleman reached out about getting a knife made for his wedding, something special to cut the cake. After a bit of back and forth, he told me his fiancée was making their own wedding dress. I told him if he sent me some of the dress material I could work it into the handle material. This was all familiar territory, bringing a lot of little pieces together to make something special.

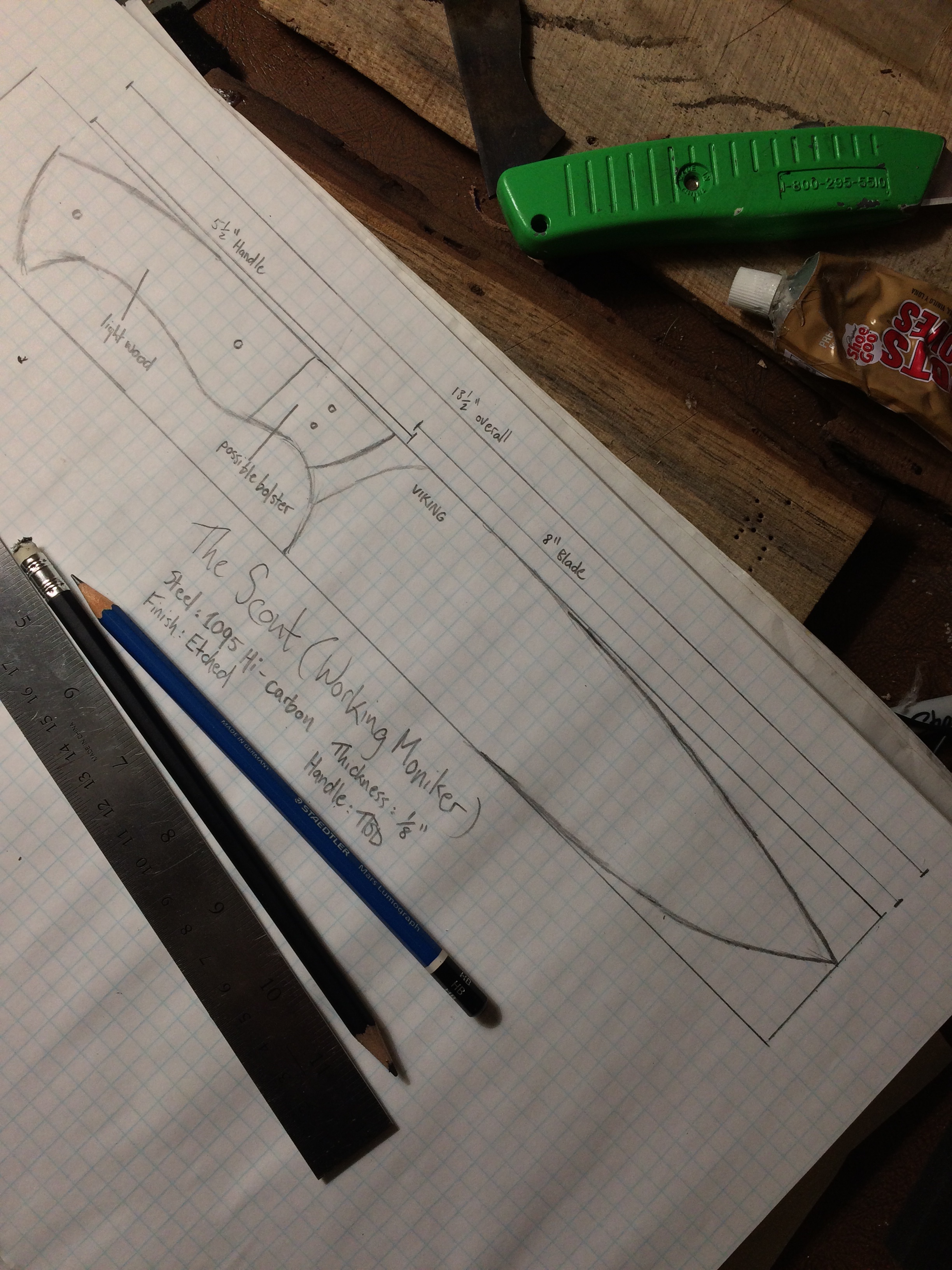

I got him some drawings together- The idea was that I would make send them a finished knife unsharpened for the cake, and after the wedding they send it back, I sharpen it, and they can then use it in their kitchen.

I used some contrasting colors to give an idea of what the knife handle COULD look like. I didn’t know what the dress material would look like.

Laying out the template

Copied on to the steel

Profiled

Removing some material before hardening

Into the forge

Grind some more

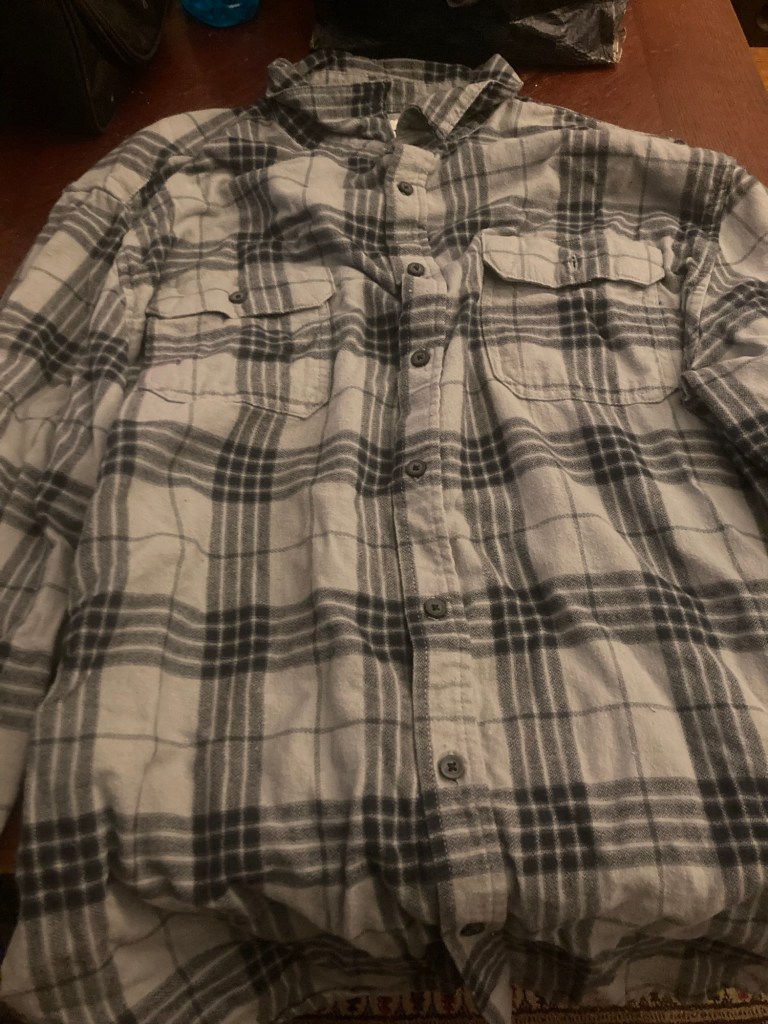

One of the clothing articles they sent me was the shirt the groom proposed in

Some of the dress material, a shimmery chiffon mesh

There was also some black stretchy dress material

Layered together to create a pattern

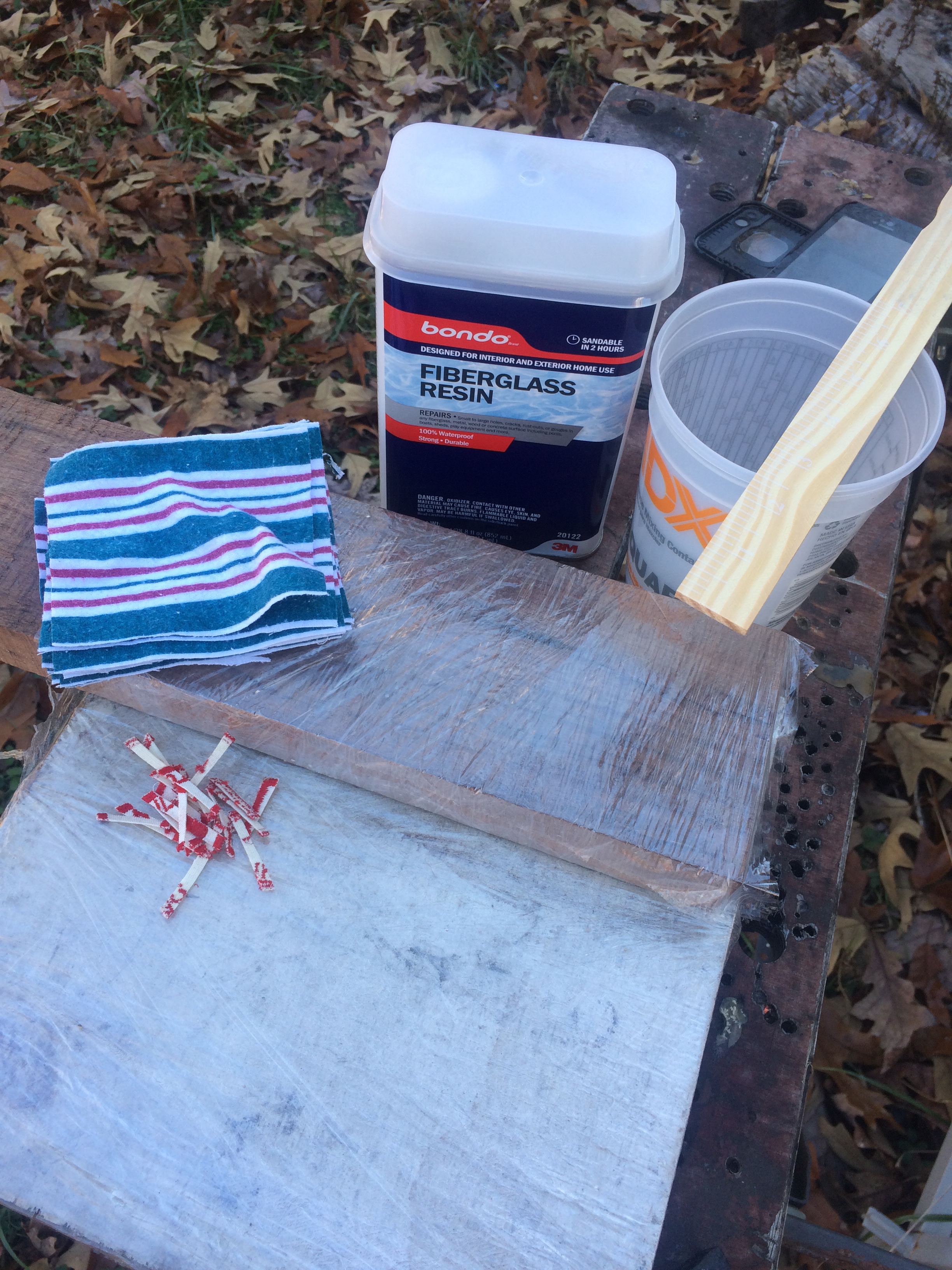

This will all get layered together with fiberglass resin

All smashed together

Cured

Everything properly smashed together

Back to the bladework, handsanding

Satin finish

Bit of brass for the bloster

Drilling before shaping

Shaped

Fitted up and set with steel-reinforced JB Weld

Rivets are peened

Fitting up the handle material. The wood is Ebony

Ready for glue-up

All glued up and clamped

Profiled

Shaped

Finally started to see what this guy looks like

Depending on the light you can catch glittery bits of the chiffon